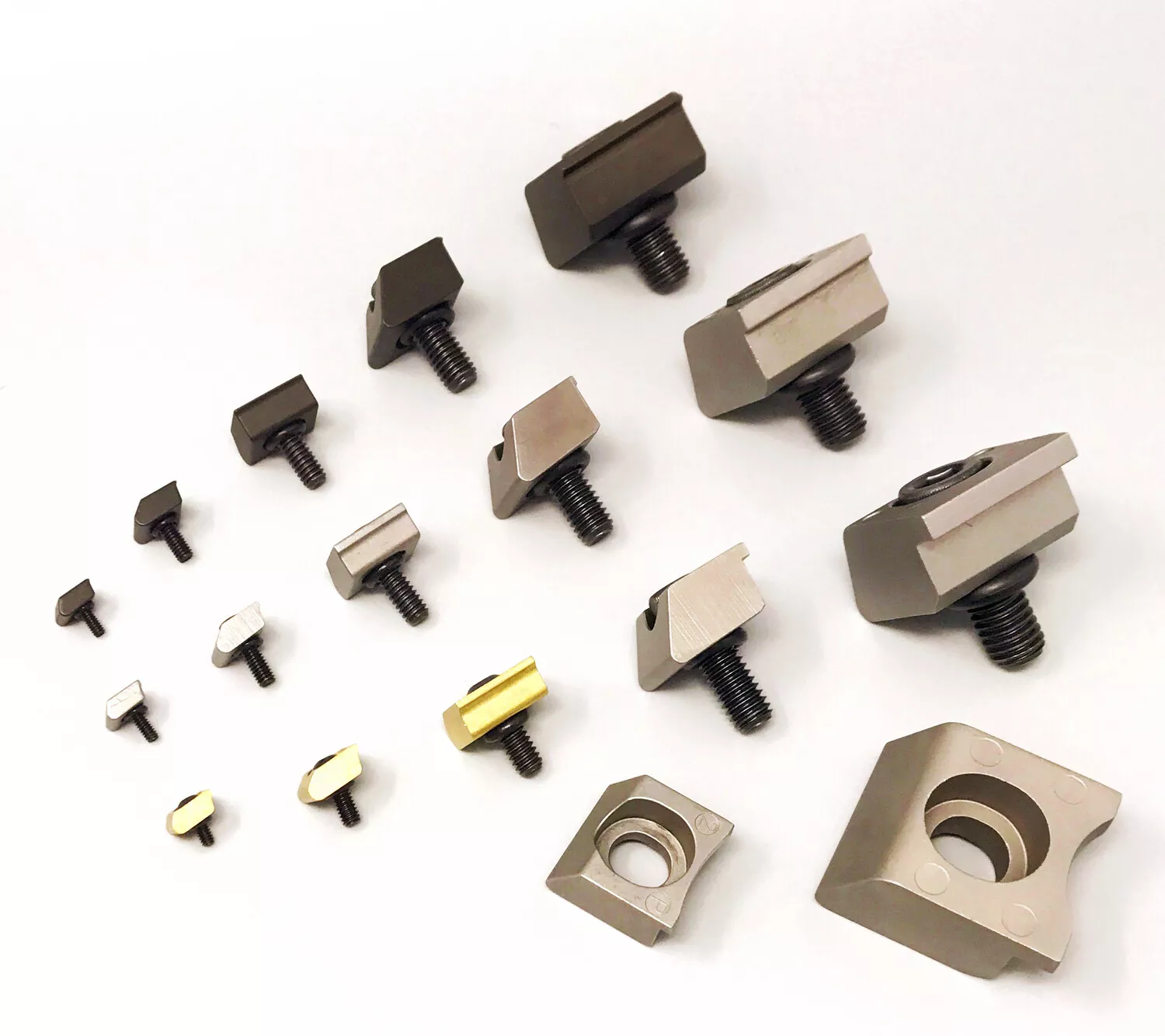

The revolutionary Pitbull® Clamp remains the lowest profile, highest holding force clamp in the industry today. High vertical and horizontal clamping forces are generated, considering the size of the Pitbull® Clamps.

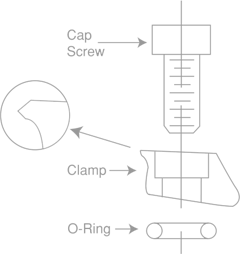

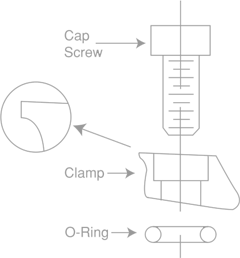

It uses a standard cap screw and an oil resistant O-ring. The Pitbull® Clamp is available in 5 sizes and several styles, a tool steel knife edge for aggressive stock removal, a tool steel blunt edge for general purpose, a brass version to help prevent marring the workpiece and a machinable version.

Also available is the Pitbull® Wear Plate. This shim provides a hard barrier between Pitbull® Clamp and fixture, preventing distortion of back wall when using aluminum or mild steel fixtures. Simple solution to keep fixtures light, maintain full clamp travel and holding forces at max pressure. Refurbish old fixtures or add to existing aluminum fixtures to maximize machining capabilities.

Unique Features of Pitbull® Clamps

- Extremely low bite

- Positive down force

- High resistance to rip-out

- Simple, sturdy, high quality design and components

- Gain maximum tool access to your work

- Virtually eliminate lost work

- Great option with hydraulic

- Tungsten Carbide coating can be added to increase holding force

Creating Fixtures is Easy. . . Simply:

- Machine a slot for the Pitbull® Clamp.

- Drill and tap a hole for the cap screw.

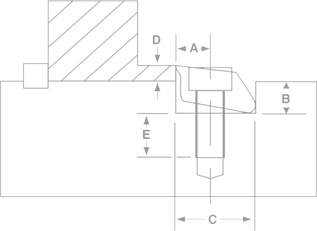

- Assemble the clamp as shown in the diagram.

- Position clamp as shown in diagram and loosely screw to fixture.

- Insert workpiece and tighten cap screw.

Metric

| Part No. | Description | A | B | Clamp Width C |

D* | E | SHCS Screw Size |

Max Torque (N.m.) |

Holding Force (N.) |

Total Throw |

No. Clamps Per Package |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 56000 | CAD | Tool Steel, Knife Edge | 3.81 | 3.55 | 9.52 | 1.90 | 6.60 | M2.5 | 1.8 | 2800 | .190 | 8 |

| 56010 | CAD | Tool Steel, Blunt Edge | 3.81 | 3.55 | 9.52 | 1.90 | 6.60 | M2.5 | 1.8 | 2800 | .190 | 8 |

| 56015 | CAD | Brass, Blunt Edge | 3.81 | 3.55 | 9.52 | 1.90 | 5.59 | M2.5 | .56 | 875 | .190 | 8 |

| 56020 | CAD | Tool Steel, Knife Edge | 5.08 | 4.75 | 12.70 | 2.54 | 9.90 | M4 | 5.6 | 6600 | .406 | 8 |

| 56030 | CAD | Tool Steel, Blunt Edge | 5.08 | 4.75 | 12.70 | 2.54 | 9.90 | M4 | 5.6 | 6600 | .406 | 8 |

| 56040 | CAD | Brass, Blunt Edge | 5.08 | 4.75 | 12.70 | 2.54 | 8.64 | M4 | 2.8 | 1750 | .406 | 8 |

| 56050 | CAD | Tool Steel, Knife Edge | 7.62 | 7.11 | 19.05 | 3.81 | 14.48 | M6 | 22.5 | 16000 | .610 | 6 |

| 56060 | CAD | Tool Steel, Blunt Edge | 7.62 | 7.11 | 19.05 | 3.81 | 14.48 | M6 | 22.5 | 16000 | .610 | 6 |

| 56065 | CAD | Brass, Blunt Edge | 7.62 | 7.11 | 19.05 | 3.81 | 11.18 | M6 | 5.6 | 4200 | .610 | 6 |

| 56070 | CAD | Tool Steel, Knife Edge | 10.16 | 11.43 | 25.4 | 6.35 | 18.03 | M10 | 40.6 | 26000 | 1.270 | 4 |

| 56075 | CAD | Tool Steel, Blunt Edge | 10.16 | 11.43 | 25.4 | 6.35 | 18.03 | M10 | 40.6 | 26000 | 1.270 | 4 |

| 56080 | CAD | Tool Steel, Knife Edge | 15.24 | 16.26 | 38.1 | 9.52 | 19.56 | M12 | 145.0 | 50000 | 1.900 | 2 |

| 56085 | CAD | Tool Steel, Blunt Edge | 15.24 | 16.26 | 38.1 | 9.52 | 19.56 | M12 | 145.0 | 50000 | 1.900 | 2 |

|

|

Both versions of the tool steel clamps generate the same clamping pressure. However, the knife edge clamps bite into the material for more aggressive machining, while the blunt edge is less likely to mark the workpiece. |

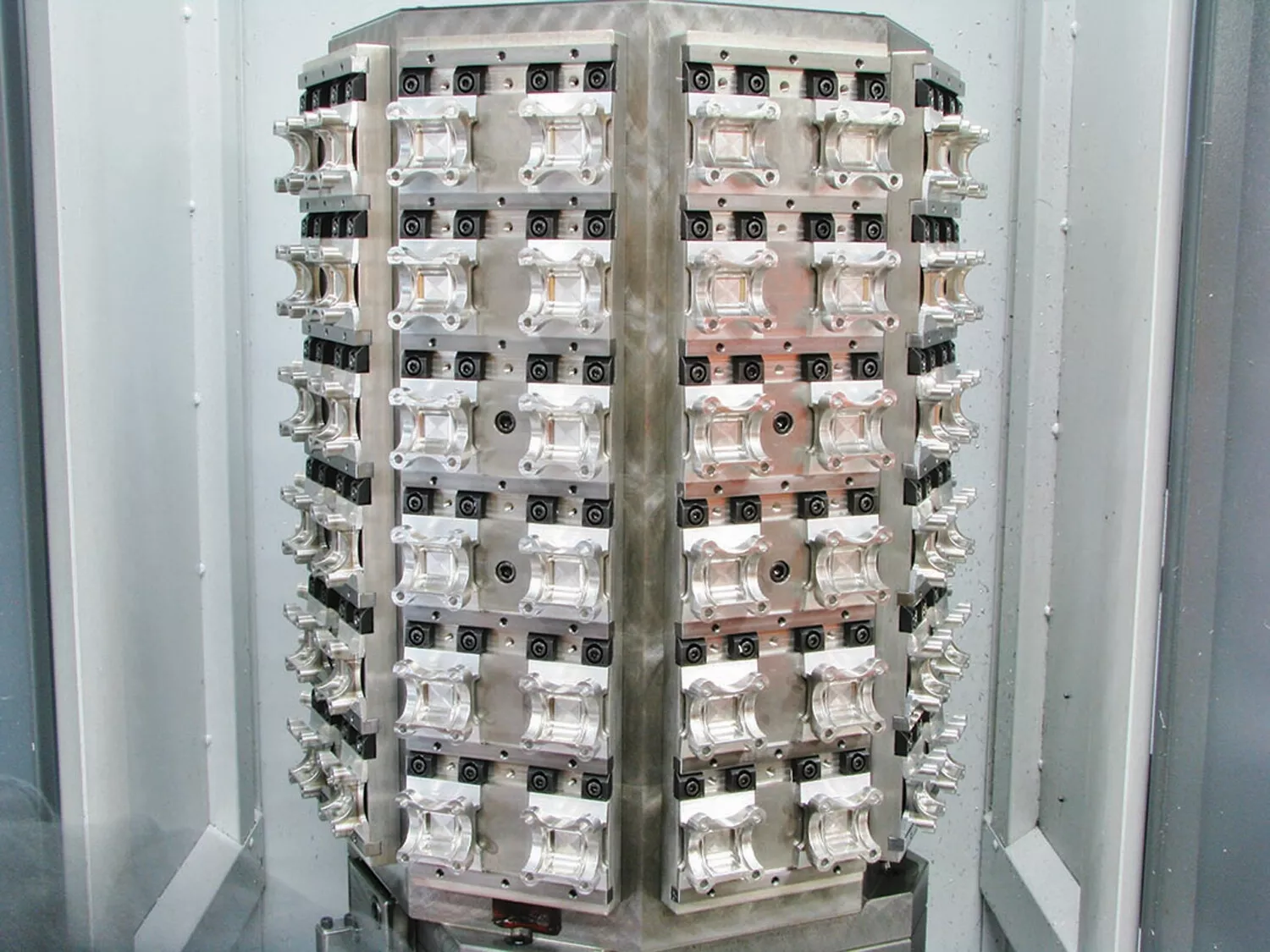

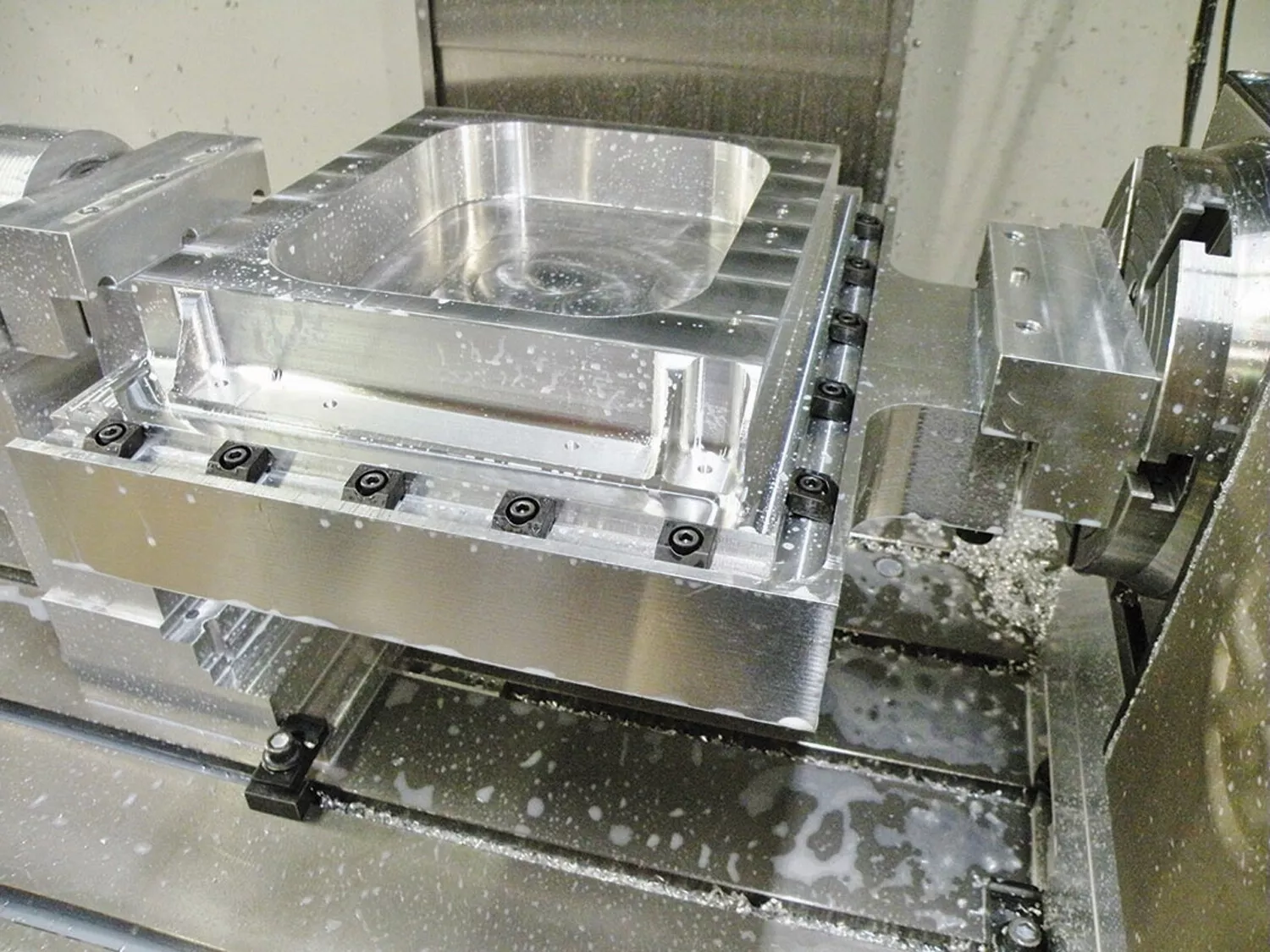

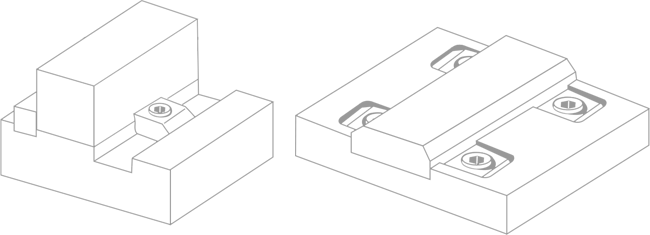

Fixture Examples |

|

|

Using a steel rail behind clamp in aluminum fixtures when applying maximum torque prevents displacing metal at pivot point. |